Differential air pressure in your data centre

In a data centre, efficient cooling is crucial for the proper operation and reliability of your IT equipment. The circulation of cool air around server racks plays a pivotal role in optimising energy costs, a significant operational expense (OpEx) in data centres. Analysis of this airflow with differential air pressure sensors optimises data centre operations.

How differential air pressure sensors improve cooling

Differential air pressure sensors play a vital role in enhancing cooling and airflow within your data centre. By utilising differential pressure sensors to monitor your system, you gain insights into airflow patterns and efficiency throughout the facility. For example, they can detect issues like improper sealing of underfloor tiles, air leaks or obstructions in the airflow.

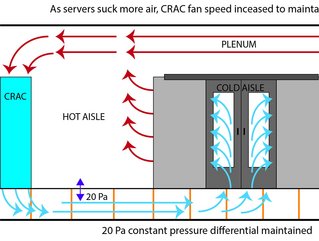

It’s essential to note that differential pressure measures the air pressure difference (∆P) between two areas, not the airflow rate itself. You can place one part of the sensor in the hot aisle and another in the cold aisle to assess proper airflow from cold to hot. A positive pressure differential in the hot aisle indicates potential hot air leakage into the cold aisle. Differential pressure is measured in Pascals.

Another option is to position pressure tubes at the front and rear of server cabinets. The front of the cabinet should always maintain higher pressure than the rear. This ensures efficient cooling by enabling air to flow from areas of high pressure to low pressure, though it doesn’t measure airflow volume, only the force of air movement.

Benefits of analysing differential pressure zones and airflow

Analysing differential pressure zones and airflow in your data centre provides several advantages:

- Optimise airflow and cooling efficiency and make necessary adjustments.

- Identify incorrect or misdirected airflow and pressure issues.

- Receive alerts for airflow changes, indicating potential leaks or cooling performance changes.

- Detect potential HVAC or cooling fan failures.

- Visualise and verify cooling and air handling efficiency.

- Correlate air pressure and flow changes with temperature variations when combined with temperature sensors.

- Achieve quick returns on investment by optimising cooling systems and reducing energy costs. Differential air pressure can also be used to control CRAC fan speeds.

The improved cooling performance will quickly return your investment in, the monitoring system, by optimising the airflow and cooling systems you can cut your energy bill. Differential air pressure can also be used as an input to control CRAC fan speeds as discussed in this article.

Installation of differential pressure sensors

When installing differential pressure sensors, locate two areas with different air pressures; areas with higher airflow always have different pressures than those with lower flow rates. Typical monitoring areas include server racks, between data centre aisles, underfloor perforated tiles, vents and air plenums.

These are the typical areas for monitoring:

- Server racks

- Between aisles in a data centre and between underfloor perforated tiles

- Vents and air plenums

Installing a differential pressure sensor is usually as simple as placing two pressure sensing tubes extending from the sensor into their designated monitoring zones:

- Position one tube in a higher-pressure zone with faster airflow, such as the base of a server cabinet where air intake occurs.

- Place the second tube in an ambient area with minimal airflow, like the top of the cabinet.

The resulting pressure differential reading indicates airflow degree through the cabinet. Keep in mind that this reading reflects relative airflow, not the exact airflow rate. A lower differential pressure indicates a lower airflow rate, while a higher pressure value suggests more substantial airflow between high- and low-pressure zones.

Utilising differential pressure for fan speed control

You may wish to utilise the differential pressure sensor data as an input to a control system for your CRAC fan speed. As servers ramp up they typically get hotter and so their fan speed increases sucking more cold air through them. You must match your cooling systems supply air to meet the demands of the servers. Too much and you are wasting energy, too little and the servers are starved of cold air resulting in potential thermal overload. You should aim for a very slight positive pressure in your cold aisle to make sure that the cold air is pushing through the servers. If there is a negative pressure it means there is a build up of hot air at the rear of the racks, which will be trying to find its way back to the cold aisle.

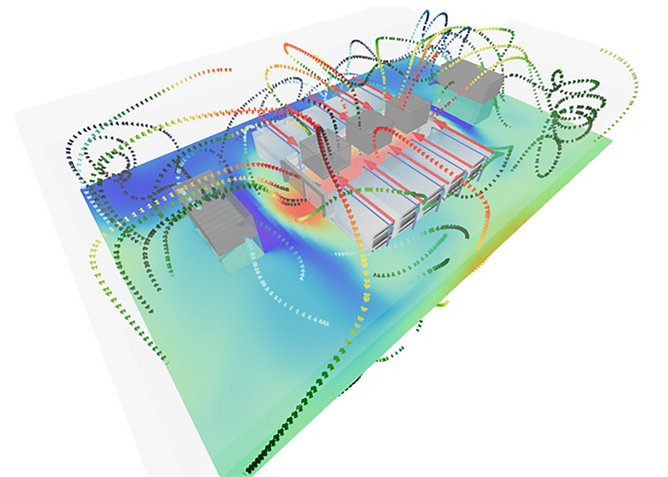

The same can occur if there are air leaks, you would need to balance the pressure. Should there be a leak in your cold aisle, air will escape causing a pressure change. Of course, in this situation you should identify the cause of the leak, such as a missing blanking panel, and fix this. Tools such as AKCP’s sensorCFD™ can be utilised for this kind of analysis.

How can AKCP help?

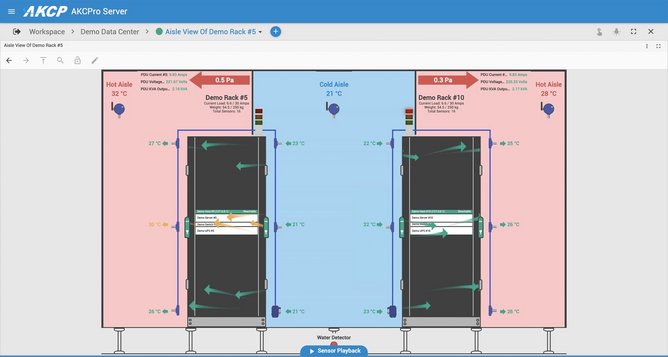

To help monitor your data centre cooling, AKCP has multiple sensors available. In addition to the Airflow Sensor which can detect the presence or absence of the airflow, you can use our Cabinet Analysis Sensors to help you get a visual representation of each rack in your data centre, the temperatures, differential pressures and the flow of air. The data from the differential air pressure sensors can be used to optimise your airflow, improving energy efficiency.

Thermal mapping for IT cabinets

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of the airflow. You can monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units.

Differential temperature (△T) and thermal maps

The cabinet thermal maps consist of two strings of 3x Temperature and 1x Humidity sensor. With these sensors, you can monitor the temperature at the front and rear of the cabinet, top, middle and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

******

For more insights into the world of Data Centre - check out the latest edition of Data Centre Magazine and be sure to follow us on LinkedIn & Twitter.

Other magazines that may be of interest - Mobile Magazine.

Please also check out our upcoming event - Cloud and 5G LIVE on October 11 and 12 2023.

******

BizClik is a global provider of B2B digital media platforms that cover Executive Communities for CEOs, CFOs, CMOs, Sustainability leaders, Procurement & Supply Chain leaders, Technology & AI leaders, Cyber leaders, FinTech & InsurTech leaders as well as covering industries such as Manufacturing, Mining, Energy, EV, Construction, Healthcare and Food.

BizClik – based in London, Dubai, and New York – offers services such as content creation, advertising & sponsorship solutions, webinars & events.